HKXCAST One-Stop Aluminum Alloy Product Solutions Provider Email :hkxcast@163.com

Learn about HKX

Die casting is widely used to produce precision components for automotive parts, electronics housings, industrial machinery, aerospace components, consumer appliances, and medical equipment.

HKX uses different machines in die casting processing. These are classified into:

2500T Die-casting machine,

800TDie-casting machine,

500TDie-casting machine,

280TDie-casting machine,

100t mold closing machine,

CNC lathe,

Four axis machining center

The following are some of the most common metals used for high-quality die casting production:

Aluminum

Zinc

Magnesium

Copper

Brass

Lead & Tin

HKX also works with custom alloy formulations to meet specific project requirements. Our die casting facility is equipped to handle these materials for various industries including automotive, electronics, consumer goods and industrial equipment manufacturing.

HKX uses various techniques in die casting processing. These are classified into mold design, melting & injection, ejection, and finishing.

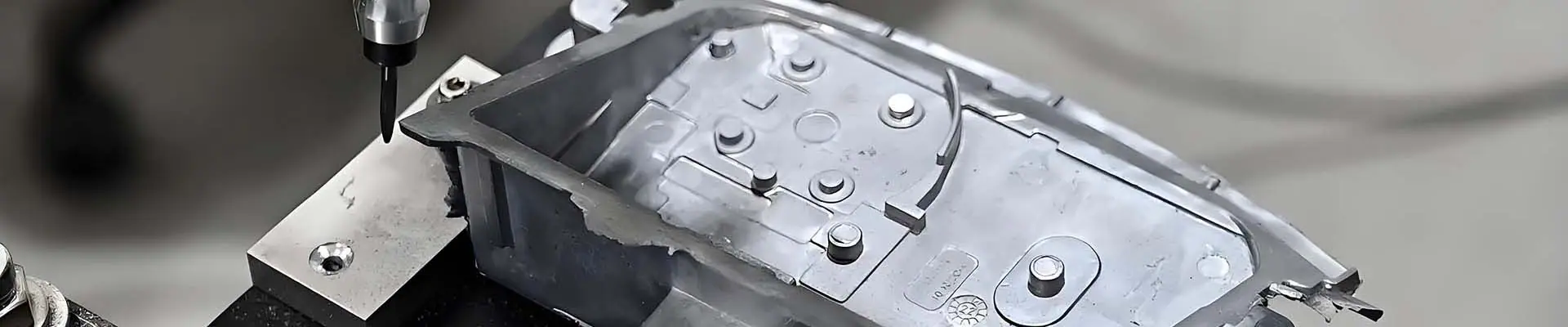

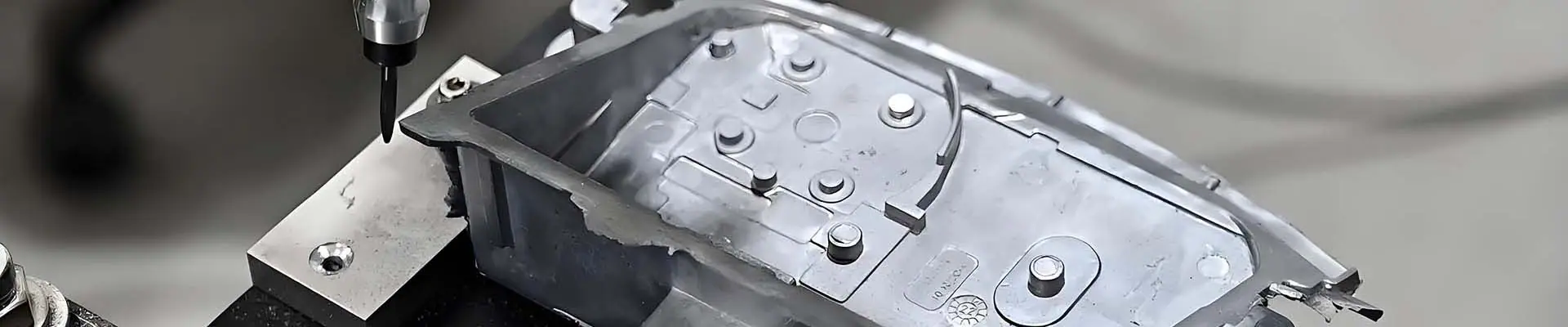

Mold design is a crucial step in die casting, where high-precision steel molds (dies) are created to shape molten metal.

HKX utilizes advanced engineering and simulation software to ensure optimal mold design for accuracy, efficiency, and durability.

Key mold design considerations include:

This process involves melting metal alloys and injecting them into the mold under high pressure.

HKX employs advanced furnaces and injection systems to ensure precise temperature control and fast cycle times.

Different injection methods include:

After solidification, the finished part is ejected from the mold.

HKX uses automated ejection systems to minimize damage and maintain consistency.

Ejection techniques include:

Finishing enhances the final product’s appearance, durability, and functionality.

HKX applies various finishing techniques to improve corrosion resistance, strength, and surface quality.

Common finishing methods include:

By using these advanced techniques, HKX ensures high-quality, precision-engineered die-cast components for various industries.

Die casting is a manufacturing process that produces metal parts by forcing molten metal under high pressure into a mold cavity.

Furthermore, the process of die casting is highly precise and requires advanced expertise.

HKX begins the process by melting metal alloys and injecting them into a steel mold (die), where they solidify into the desired shape, resulting in strong, high-quality, and dimensionally accurate components.

whatsapp

whatsapp

Email :hkxcast@163.com

We will reply to you within 24 hour

Email :hkxcast@163.com

Back to Top