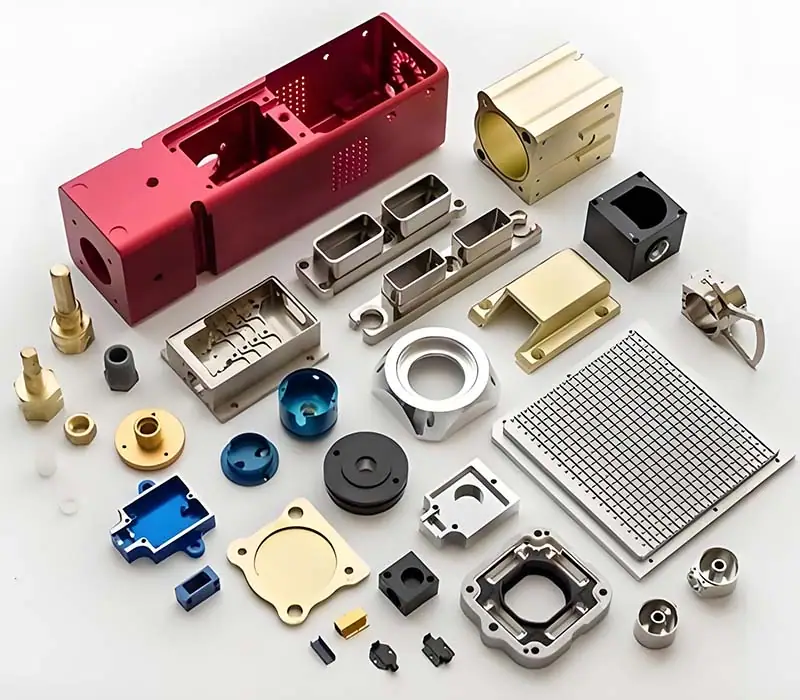

Surface treatment

HKX provides professional surface finishing services covering a wide range of materials such as metals, composites and plastics. Regardless of the manufacturing process used for your parts, we can significantly enhance the appearance and functional performance of your products through high-quality surface treatment technology to help you beautifully present creative prototypes or precision parts.