Multi-slide die casting is a specialized form of hot-chamber die casting that uses four or more slides moving in different directions to create complex, high-precision metal parts. Unlike conventional two-plate or three-plate systems, multi-slide die casting enables tooling from multiple axes, allowing for intricate geometries without secondary machining.

This technology is ideal for small parts with tight tolerances, commonly used in industries requiring mass production with consistent quality and minimal material waste.

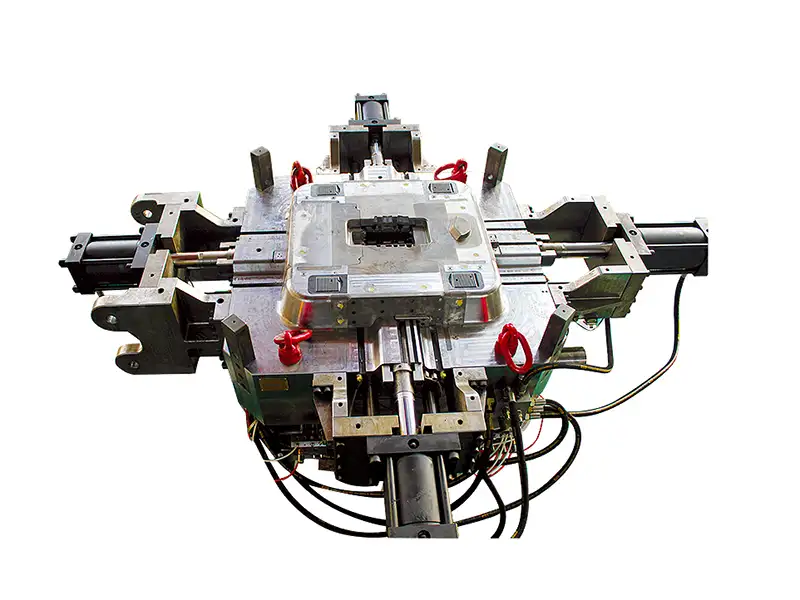

die casting mold

How Multi-Slide Die Casting Works

At the core of the process is a precision die that incorporates multiple moving slides. Each slide contains a tool steel insert that shapes one side of the component. When molten metal—usually zinc or magnesium—is injected into the mold, the slides move simultaneously to lock the cavity, then retract to release the part once solidified.

Key process features:

- Fast cycle times (as low as 2–5 seconds per part)

- High dimensional repeatability

- Automation-friendly setup

- Efficient for small-to-medium batch production

Key Advantages of Multi-Slide Die Casting

- Superior Precision: Achieves tolerances as tight as ±0.001 inches, reducing the need for post-machining.

- Shorter Cycle Times: Simultaneous motion of slides and reduced cooling time result in faster production.

- Lower Material Waste: Minimal flash and no need for trimming in many cases.

- Design Flexibility: Supports undercuts, complex features, and thin walls.

- Longer Tool Life: Less thermal fatigue due to shorter injection paths and uniform fill patterns.

These benefits translate to better ROI and reduced total manufacturing costs over time.

Applications and Industries

Multi-slide die casting is widely adopted across industries that demand precision, durability, and cost efficiency:

- Automotive: Connectors, gear housings, fuel system components

- Consumer Electronics: Camera parts, laptop hinges, smartwatch frames

- Medical Devices: Miniature implant casings, surgical instrument parts

- Telecommunications: RF shields, antenna brackets, enclosures

Its versatility makes it an ideal solution for OEMs requiring tight specifications and high-volume consistency.

Multi-Slide vs Traditional Die Casting

| Feature | Multi-Slide Die Casting | Traditional Die Casting |

|---|---|---|

| Tolerance | ±0.001 in | ±0.003–0.005 in |

| Part Complexity | High | Moderate |

| Tooling Cost | Higher upfront | Lower upfront |

| Cycle Time | Faster (2–5 sec) | Slower (10–30 sec) |

| Secondary Operations | Often unnecessary | Frequently required |

While traditional die casting is suitable for larger and simpler parts, multi-slide excels in producing small, intricate components with minimal post-processing.

Considerations for Choosing Multi-Slide Die Casting

Before choosing multi-slide die casting, consider the following factors:

- Volume: Best suited for high-volume production where tooling costs are amortized.

- Complexity: Ideal for parts with undercuts, fine details, or multi-axis features.

- Material: Primarily optimized for zinc and magnesium alloys.

- Partner Capability: Select suppliers with in-house tooling design and fast-cycle hot-chamber machines.

Environmental and Economic Impact

Multi-slide die casting is more sustainable than many traditional metalworking methods:

- Lower Energy Usage: Shorter cycle times mean less power consumption per part.

- Material Efficiency: Reduced scrap rates and higher metal utilization.

- Smaller Footprint: Compact machinery and fewer secondary processes reduce overall factory space and emissions.

These attributes support both economic savings and ESG (Environmental, Social, and Governance) goals.

Conclusion

Multi-slide die casting offers unmatched precision, speed, and design flexibility for producing complex metal parts. As demand grows for miniaturized and high-performance components, this process will play an increasingly important role in sectors like automotive, consumer electronics, and medical technology. Manufacturers looking to reduce costs and lead time while improving part quality should seriously consider multi-slide die casting as their go-to solution.art quality should seriously consider multi-slide die casting as their go-to solution.

Frequently Asked Questions (FAQ)

1. What is multi-slide die casting?

Multi-slide die casting is an advanced form of hot-chamber die casting that uses four or more sliding components to form complex, high-precision metal parts. It allows for faster cycle times and supports intricate part geometries without the need for secondary machining.

2. What are the advantages of multi-slide die casting?

The main advantages include ultra-high precision, fast cycle times, minimal material waste, long mold life, and the ability to create complex features and undercuts that are difficult with conventional die casting.

3. Which materials are used in multi-slide die casting?

Zinc alloys (such as Zamak) are the most common materials used in multi-slide die casting due to their excellent flow characteristics, low melting point, and suitability for high-volume production. Some systems also support magnesium alloys.

4. How is multi-slide die casting different from traditional die casting?

Unlike traditional die casting that typically uses two-part molds, multi-slide systems inject metal into molds with multiple moving slides, enabling higher part complexity, tighter tolerances, and less post-processing.

5. What industries benefit most from multi-slide die casting?

Industries such as automotive, consumer electronics, medical devices, and telecommunications frequently use multi-slide die casting to produce small, detailed, high-volume parts with consistent quality.

6. Is multi-slide die casting cost-effective?

While initial tooling costs may be higher, the long-term savings from reduced cycle times, minimal secondary operations, and lower defect rates make multi-slide die casting highly cost-effective for medium to high production volumes.