CNC (Computer Numerical Control) technology has drastically changed the landscape of modern manufacturing, making processes faster, more precise, and more efficient. The evolution of CNC has led to advancements in industries ranging from automotive to aerospace and medical devices. In this article, we explore the history of CNC, its development, and its applications in modern industries. Additionally, we’ll showcase how HKX Die Casting has embraced CNC technology to enhance precision and quality in die casting processes.

What is CNC Machining?

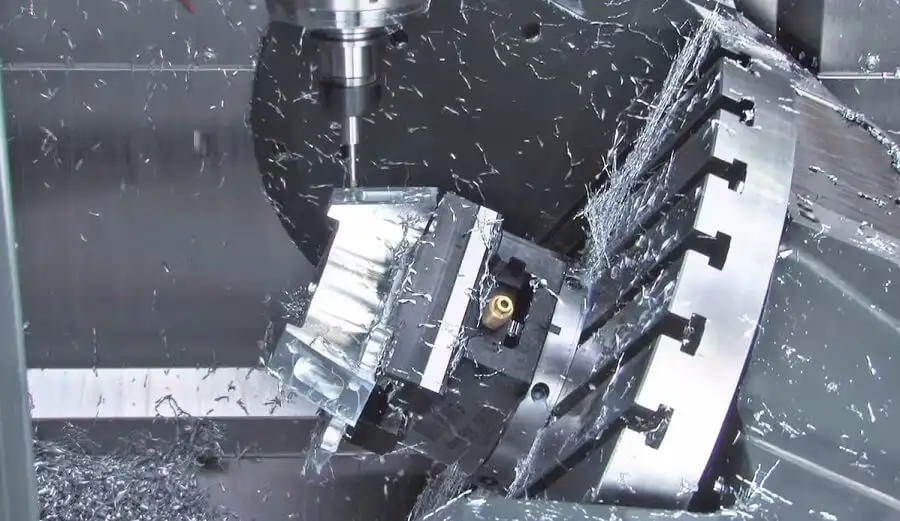

CNC machining is a manufacturing process that uses computer-controlled machines to perform a variety of tasks such as cutting, drilling, milling, and shaping. Unlike traditional manual machining, CNC machines are programmed with specific instructions that allow for higher precision and automation.

Advantages of Using CNC Machining

- Precision and Accuracy: CNC machines can produce highly detailed and accurate parts, ensuring minimal errors.

- Increased Productivity: Automated CNC processes significantly reduce production time, leading to higher efficiency.

- Flexibility: CNC allows for rapid prototyping and adjustments in designs, making it ideal for custom manufacturing.

- Cost-Effectiveness: Over time, CNC reduces labor costs and material wastage, leading to cost savings.

At HKX Die Casting, CNC technology plays a crucial role in creating high-precision molds and parts, improving the overall efficiency of our die casting process.

CNC History

The history of CNC technology is rooted in the development of Numerical Control (NC) machines, which were first used in the late 1940s and early 1950s. These early machines, though groundbreaking, were limited by the manual control systems that operated them.

The First CNC Machine

The concept of CNC began with the invention of NC machines in the 1940s, driven by the need for automation during World War II. The first CNC machine was developed in the 1950s, with significant contributions from John T. Parsons, who is often regarded as the father of NC. These early machines were mechanical but laid the groundwork for computer-driven systems that followed.

Development of CNC Technology

- 1952-1958: Early NC machines were controlled by punched cards and were manually operated, making them slow and prone to errors.

- 1967-1972: The development of digital computers and microprocessors led to the transformation of NC machines into fully automated CNC machines, which could execute complex tasks more efficiently and precisely.

- 1976-1989: The rise of multi-axis CNC machines during this period marked a major leap forward, enabling more complex and intricate parts to be produced. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems also began to integrate with CNC technology during this time.

Today’s CNC Industry

Today, CNC technology is an integral part of manufacturing in nearly every industry, from automotive and aerospace to medical devices and die casting.

Modern CNC Machines

With continuous advancements in technology, modern CNC machines are equipped with multi-axis capabilities, enhanced automation, and even artificial intelligence (AI) integration. Smart CNC systems now collect data to optimize performance, improving efficiency and reducing errors.

CNC Industry Advancements

Some of the latest trends in the CNC industry include:

- 5-axis CNC machines that allow for more precise and complex manufacturing.

- AI-powered CNC systems that learn and adapt for better production outcomes.

- Internet of Things (IoT) integration, which allows machines to communicate with one another and ensure seamless operations.

At HKX Die Casting, we have embraced these cutting-edge CNC advancements to ensure that we deliver the highest quality products with maximum efficiency.

CNC Machining Applications

CNC technology is used across many industries due to its precision, efficiency, and versatility.

Industrial Applications

CNC machines are essential in industries such as automotive, aerospace, and heavy machinery. In the automotive sector, for example, CNC is used to produce high-precision engine components, ensuring optimal performance and safety.

At HKX, we use CNC technology for die casting, creating durable, high-precision molds and parts for industrial applications. CNC machining ensures the accuracy of every component, minimizing the risk of defects and ensuring consistency across production batches.

Manufacturing Applications

From medical devices to aerospace components, CNC machining is crucial in producing high-quality products that require precision. CNC is used in manufacturing surgical instruments, prosthetics, and even spacecraft components, all of which must meet strict quality standards.

Conclusion

The history of CNC machining is a testament to the incredible strides made in manufacturing technology. From the first NC machines to today’s advanced CNC systems, CNC technology has transformed the way we produce parts and products. As the industry continues to evolve, innovations in automation, AI, and IoT promise even greater efficiency and precision.

At HKX Die Casting, we leverage state-of-the-art CNC technology to provide high-quality die casting solutions that meet the demands of modern industries. Whether you need automotive, aerospace, or medical device components, our CNC-driven processes ensure that your products are made to the highest standards.

FAQ

What is CNC machining?

CNC machining refers to the use of computer-controlled machines to automate the process of cutting, shaping, and finishing materials with high precision.

How does CNC technology improve manufacturing?

CNC improves manufacturing by reducing human error, increasing efficiency, and allowing for the production of complex designs that are difficult to achieve with manual machining.

Why is CNC important for die casting?

CNC technology enhances the precision and consistency of die casting processes, allowing for high-quality molds and parts that meet stringent industry standards.